+1 (754) 364 2331

4274 Eastminster Rd. Davenport, FL 33837

United States

Ave. Arroyo el Molino #1001, Int. 511 La Paloma, 20115 Aguascalientes, Ags. México

4512 Hacienda Shoppe Ctr Suite 11 #33 00610 Anasco, Puero Rico

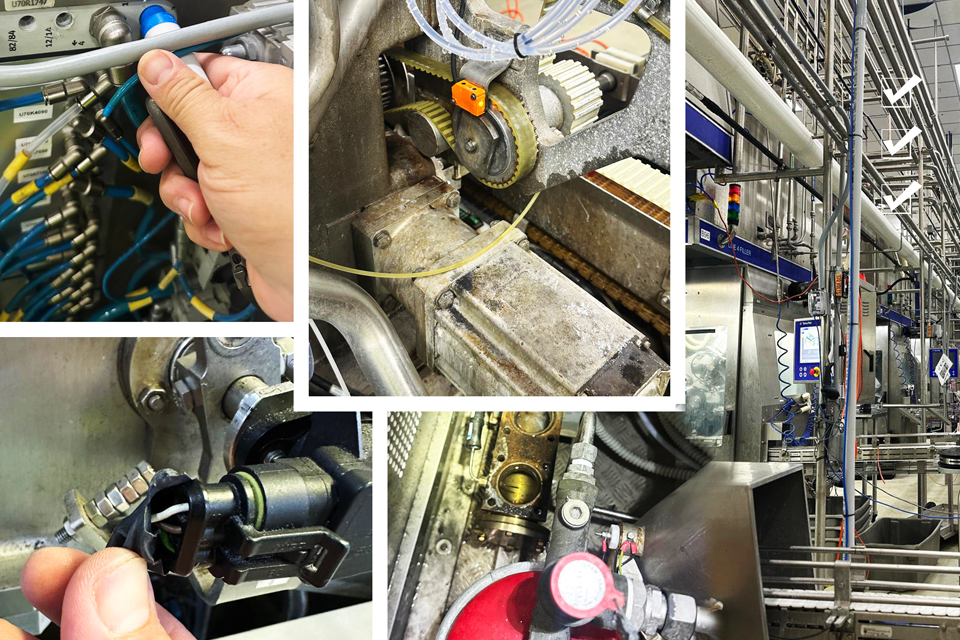

PROCESS AND PACKAGING

SOLUTIONS

Food Packaging

Comprehensive engineering service for freezing equipment, slicers, thermoformers, and seasoning equipment for the food industry, such as sausages and cheeses.

Beverage Packaging

Specialized and comprehensive service in aseptic and non-aseptic packaging equipment for liquid foods (juice, dairy, sauces, broth, etc.) in presentations such as carton, plastic, and bags from OEMs like Tetra Pak, TecnoItalia, ESSI, Dupont, Krones.

Process Equipment

Engineering solutions for pasteurization process machinery (separators, homogenizers, pasteurizers, Alsafe, Aldose, aseptic tanks) from multiple brands like TetraPak, GEA, Stork, APV-SPX, Gaulin.

LEADING THE WAY

WE ARE SILBEC

The dynamism of our business has led us to be leaders in solutions for your unique needs.

We are the strategic ally that your company needs.

Elevate your business today with SILBEC TECHNOLOGY GROUP let’s grow together.

OUR HISTORY

We began our operations in 2007 under the name CIMMA TECHNOLOGY, focusing on electromechanical industrial services. In 2008, market demand led us to enter the biomedical sector, serving hospitals in the Bajío region with a strong presence in the State of Aguascalientes. By 2010, we expanded into security systems. The synergy and dynamism of the market drove us in 2012 to the automation field, and in 2015, we added industrial machinery repair to our service portfolio.

In 2016, we paused our operations and reactivated them in 2020 under the name SILBEC TECHNOLOGY GROUP. With a core business focus on carton packaging for beverages, between 2020 and 2022, we expanded our services to include bags, PET, and UHT processing technology. In 2022, we entered the North American market by opening an office in Miami. By 2023, we captured 39% of our group sales in this market. Starting February 1, 2024, we continued our expansion in the packaging sector, now focusing on the Food Pack area (cold cuts and packaged foods).

Growth is part of our DNA. In 2024, we segmented our business into three divisions: Beverage Packaging Division, Processing Division, and Food Packaging Division, while maintaining our focus on our core business and addressing all aspects of it.

NUESTRA HISTORIA

Iniciamos nuestras operaciones en 2007 bajo el nombre de CIMMA TECHNOLOGY, enfocados en el servicio industrial electromecánico. En 2008, la demanda del mercado nos llevó a incursionar en el sector biomédico, atendiendo hospitales en la región del Bajío, con una notable presencia en el Estado de Aguascalientes. Para 2010, expandimos nuestras actividades al área de sistemas de seguridad. La sinergia del mercado y su dinamismo nos condujeron en 2012 al campo de la automatización, y en 2015, incorporamos la reparación de maquinaria industrial a nuestro portafolio de servicios.

En 2016, hicimos una pausa en nuestras operaciones, reactivándolas en 2020 bajo el nombre de SILBEC TECHNOLOGY GROUP. Enfocándonos en el envasado en cartón de bebidas, durante el período de 2020 a 2022, ampliamos nuestros servicios para incluir bolsas, PET y equipos de procesamiento en tecnología UHT. En 2022, iniciamos operaciones en el mercado norteamericano con la apertura de una oficina en Miami. En 2023, captamos el 39% de nuestras ventas en este mercado como grupo. A partir del 1 de febrero de 2024, continuamos nuestra expansión en el sector del envasado, ahora en el área de Food Pack (carnes frías y alimentos empaquetados).

El crecimiento es parte de nuestro ADN. En 2024, segmentamos nuestro negocio en tres divisiones: Beverage Packaging Division, Processing Division y Food Packaging Division, manteniendo siempre el enfoque en nuestro Core Business y atendiendo todas las aristas de este.

What We Offer

CORRECTIVE MAINTENANCE

Minimization of downtime due to failures.

Quick restoration of equipment functionality.

Reduction of the negative impact on production and operations.

PREVENTIVE MAINTENANCE

Reduction of unplanned downtime.

Lower risk of catastrophic failures.

Increased equipment efficiency and performance.

Cost savings on emergency repairs and replacements.

PREDICTIVE MAINTENANCE

Early identificacion and resolution of problems before they occur can save up to 40% in maintenance costs.

Generates greater efficiency in the companies businnes.

Increasing the productivity of the lines, optimizing stock and reducing human error.

20 +

Years of Experience

2,500 +

Projects Completed

15 +

Presence in Countries

PROJECT MANAGEMENT

From start to finish, every project needs a plan that outlines how things will get off the ground, how they will be built, and how they will finish. Elevate your projects to new heights with our intuitive tools and expert support. Try it today and experience the difference!

BRANDS WE PROUDLY SERVE

Ready To Start A New Project ? Contact Us

+1(754)3642331